SILO & ACCESSORIES

Gayatri Engimech pvt. Ltd. provides a complete solution to your silo requirements. It offers a wide range of storage silos for powder products like Cement/Fly Ash GGBS, Lime, Microsilica, Bentonite, and others for the Construction Industry. The capacities vary from 30 to 200 tons, as per the client’s requirements.

Vertical silo : It is the best choice for short-distance transportation and quick for erection. Being transported as a single piece at the site, all that needs to be done is lift the silo and put it on the foundation. Another benefit of welded silos is their leakproof structure.

- Small land occupancy.

- Low cost.

- Leakproof.

- Can be made in a higher capacity.

HORIZONTAL SILO : Horizontal Silo is often used for a building site, urban work operation, road work, or where skyspace is not available.

- Convenient for inspection and maintenance.

- Easy to install and disassemble.

- Less foundation required.

- Safe with no seismic risk to the job site or surrounding area.

Accessories

Butterfly Valve : : A manual lever-controlled butterfly valve mounted on the bottom of the silo, stops the material flow for screw conveyor servicing.

Min/Max level indicators : It sends information to the control panel computer when the cement/fly ash quantity is low or on its maximum.

Pressure Relief Safety valve : It prevents silo from overpressure. The valve opens when the threshold pressure limit is reached.

Aeration nozzles : It ensures a continuous flow of the material to the discharge area.

AGGREGATE FEEDING CONVEYOR

Radial Conveyor for in-line bin :

Gayatri Engimech Pvt. Ltd. manufacture and supply Aggregate Feeding Belt Conveyors for Handling Sand and Aggregates in RMC batching Plants. This system allows easy aggregate/sand feeding without any extra costs for the ramp. This will be a radial belt conveyor for feeding material directly into the In-line bins. Capacities vary as per the client’s requirements.

Also, we are providing Heavy Duty Rollers & Pulleys which ensure hassle-free and long life work performance at its user end. These Aggregate Feeding Belt Conveyors are widely available in various specifications and capacities.

Belt Conveyor with rotary chute:

This system is used for Cross-Bin type plants. Due to the Cross-Bin design, the design aggregate bin height is quite high. In order to reduce the cost of building a two-side feeding ramp. This system allows easy aggregate feeding without any extra costs for the ramp. The aggregates are being distributed in 4 nos compartment bins with the help of a rotating chute. It is used for a large-scale project to ensure aggregate delivery, save time and improve work efficiency.

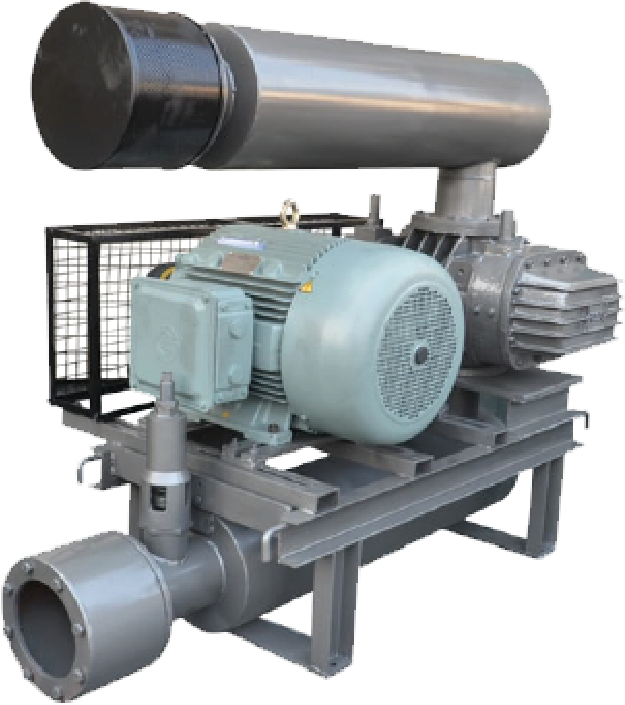

TWIN LOBE ROOT BLOWER

Used for Feeding Cement / Fly ash from bulker to silo. It’s capacity is 900m3/hr at pressure of 0.8kg/cm2 and motor of 50HP/1450 rpm. Blower rpm 1535. Along with its accessories and panel.

- Rugged Construction.

- Low Maintenance.

- Suitable for Continuous duty.